DRAIN LINING – NO DIG TECHNOLOGY

No Dig Technology is a proven and established method of placing a new pipe within an existing damaged pipe without excavation and with minimal disruption.

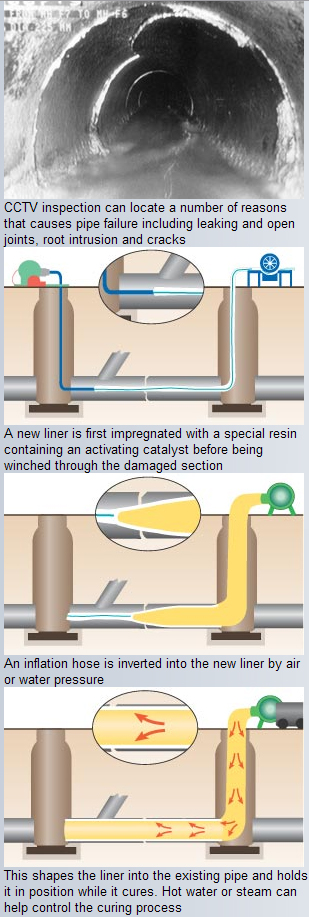

The new pipe material is similar to GRP (glass reinforced plastic) and in all cases will be superior in quality and strength to the pipe which it lines. The new pipe is moulded into the damaged pipe by an ingenious method called ‘inversion’ using water or air pressure, fitting it tightly against the wall of the existing pipe. When the inversion is complete the new pipe (which is originally flexible) is now rigid, resulting in a strong, tough pipe tightly fitted within the existing pipe with only a minimum loss of cross section of approximately 6%.

The liner is manufactured from a special dense impermeable felt and is designed and tailored to fit exactly the internal dimension of the pipe to be refubished. The thickness of the lining material can be varied according to design specifications required.

We have a selection of three special resins systems – Polyester, Silicate and Epoxy with different curing times – suitable for various conditions and applications. These are impregnated into the liner prior to installation in the pipe.

Expert Sewer Pipe Relining Solutions

The liner is suitable for sewers and vertical rainwater down pipes etc, 75mm – 300mmØ. It is resistant to most aggressive chemicals and can withstand extremely high temperatures.

A special resin containing an activating catalyst is impregnated into the pipe liner prior to installation.

Drain lining is suitable for sewers and vertical rainwater downpipes etc, 75mm – 300mØ. The liner is resistant to most aggressive chemicals and can withstand extremely high temperatures.

Once the pipe is cured, the inversion liner is removed leaving a strong and tough new pipe within the existing pipe. Any lateral pipes are reconnected by a remote controlled robotic cutter.

Long-Lasting Pipe Lining Repair Services

BENEFITS OF NO DIG TECHNOLOGY

DRAIN LINING – BENEATH HEATHROW AIRPORT BYPASS

In this case we lined 75 metres of 225 mm (9 inch) fractured clay pipe, beneath a bypass at Heathrow Airport. Using our drain lining (no dig technology), we were able to fix the drain and avoid excavation and the inconvenience of lengthy closure to the airport’s busy perimeter road.

DRAIN LINING – DOMESTIC HOUSEHOLD DRAIN

In this case, our customer had recently built expensive decking, only to find afterwards that he had a broken sewer pipe beneath it.

Using drain lining technology we were able to repair the broken pipe without damaging his decking or excavating his garden, which would’ve been both disruptive and costly.

DRAIN LINING – DOMESTIC DRAIN TO MAIN SEWER

This case also involved a broken sewer pipe. This time going from a private house in a cul-de-sac to a drain in the main road.

We were able to line the drain to repair it without having to dig up the customers driveway or the pavement and road. Again this saved not only money, but also considerably less disruption to our customer and his neighbours.